Remote Site Revolution: The Power of Industrial Modular Housing Solutions

Working in remote locations presents a unique set of challenges, especially when it comes to providing adequate and comfortable living and working spaces for your personnel. Frankly speaking, traditional construction methods can be prohibitively expensive, time-consuming, and logistically nightmarish in these environments. This is where industrial modular housing solutions for remote sites step in, offering a paradigm shift in how we approach infrastructure development in isolated areas.

In my experience, the demand for robust, adaptable, and rapidly deployable structures for industries like mining, oil and gas, construction, and disaster relief has never been higher. These sectors often operate far from established urban centers, requiring self-sufficient and resilient facilities. Industrial modular housing, also known as off-site construction or prefabricated building, is not just a trend; it's a necessity for efficient and sustainable operations in challenging terrains.

Understanding Industrial Modular Housing

At its core, industrial modular housing involves constructing building components or entire modules in a controlled factory environment. These modules are then transported to the remote site and assembled. This process offers a multitude of advantages over conventional on-site building. The controlled factory setting ensures higher quality control, reduced waste, and protection from adverse weather conditions that can plague remote sites.

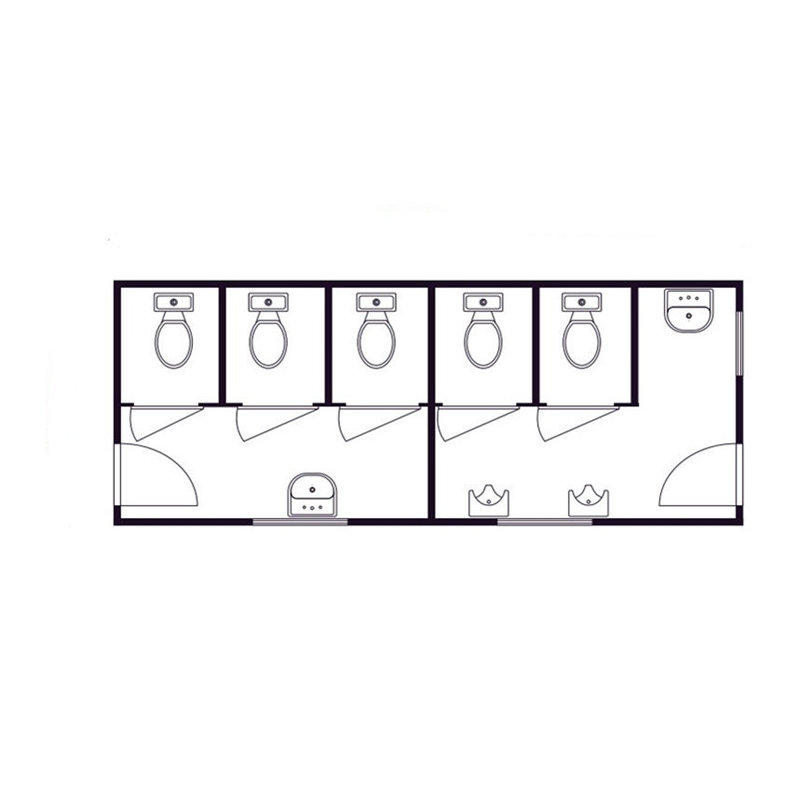

It's worth noting that the term "modular" can sometimes conjure images of temporary, low-quality structures. However, modern industrial modular housing is anything but. These are sophisticated, durable buildings designed to meet stringent building codes and specific industry requirements. They can range from simple accommodation units and ablution blocks to complex office spaces, laboratories, and even full-scale operational facilities.

The Benefits of Factory-Controlled Construction

One of the most significant advantages is the predictability of cost and timeline. Because the majority of the construction happens off-site, you eliminate many of the variables that drive up costs and cause delays in remote locations – such as unpredictable weather, labor shortages, and supply chain disruptions. This predictability allows for better project planning and budgeting.

Furthermore, the manufacturing process in a factory environment is inherently more efficient. Specialized teams work on specific tasks, leading to faster production cycles. This means your remote site can be operational much sooner than with traditional methods.

Tailoring Solutions for Diverse Remote Site Needs

The beauty of industrial modular housing solutions for remote sites lies in their inherent flexibility and adaptability. No two remote locations or projects are identical, and the modular approach allows for customization to meet specific operational and environmental demands.

Consider the diverse needs of different industries. A mining operation might require robust living quarters that can withstand harsh conditions, along with specialized workshops and storage facilities. An oil and gas exploration project might need temporary but comfortable accommodation for a transient workforce, alongside secure control rooms. A disaster relief effort, on the other hand, demands rapid deployment of essential facilities like medical centers and temporary shelters. Modular construction can be tailored to address all these scenarios.

Customization and Scalability

From the ground up, modular units can be designed to incorporate specific features. This includes:

- Climate Control: Advanced insulation and HVAC systems for extreme temperatures.

- Durability: Robust materials designed to withstand corrosive environments, high winds, or seismic activity.

- Utilities Integration: Pre-installed plumbing, electrical, and communication systems, often designed for off-grid or limited utility connections.

- Layout Flexibility: Units can be configured for single occupancy, shared living, or communal spaces, and can be expanded or reconfigured as needs change.

This scalability is a game-changer. As a project grows or its needs evolve, additional modules can be manufactured and transported to site, seamlessly integrating with existing structures. This avoids the need for costly and disruptive expansions common with fixed, on-site builds.

Logistics and Deployment: Overcoming Remote Challenges

The logistical hurdles of working in remote areas are undeniable. Transporting materials, equipment, and personnel can be a significant undertaking. Industrial modular housing solutions are designed with this in mind, often optimizing module dimensions for standard transportation methods, whether by road, rail, or sea.

Once the modules arrive at the site, assembly is typically swift. Skilled teams can erect and connect modules quickly, minimizing disruption to ongoing operations. This is a stark contrast to the weeks or months it can take to build a conventional structure from the ground up, especially when facing challenging site conditions or limited access.

Interestingly enough, the reduced on-site construction time also translates to a smaller on-site footprint and less environmental impact. Fewer personnel are required on-site for extended periods, and the reduced need for heavy machinery for prolonged durations can preserve the local environment.

Addressing Site-Specific Constraints

When designing industrial modular housing solutions for remote sites, manufacturers consider factors like:

- Site Accessibility: Can the modules be transported to the exact location? Are there limitations on road width, bridge capacity, or terrain?

- Foundation Requirements: What type of foundation is suitable for the ground conditions? Modular units can often be designed for simpler foundation systems.

- Environmental Conditions: Extreme temperatures, high winds, seismic activity, or corrosive atmospheres all influence material selection and structural design.

- Utility Availability: How will power, water, and waste management be handled? Modular units can be pre-equipped for off-grid solutions.

Many experts agree that a thorough site assessment is crucial before selecting or designing modular solutions. This ensures that the chosen system is not only fit for purpose but also practical to deploy and operate in its intended environment.

Sustainability and Cost-Effectiveness

Beyond speed and adaptability, industrial modular housing solutions for remote sites offer compelling advantages in terms of sustainability and cost-effectiveness. The controlled factory environment leads to significantly less material waste compared to traditional construction. Offcuts and excess materials can be recycled or reused more effectively within the factory setting.

Furthermore, the energy efficiency of modular buildings is often superior. Factory-controlled insulation, high-performance windows, and integrated HVAC systems can be standard features, leading to lower operational energy costs over the lifespan of the building. This is particularly important for remote sites where energy generation and supply can be expensive and challenging.

The Economic Equation

While the initial investment in modular construction might seem comparable to traditional methods, the overall cost savings are often substantial. These savings stem from:

- Reduced Labor Costs: Less on-site labor is required, and the efficiency of factory production minimizes labor hours.

- Minimized Project Delays: Predictable timelines avoid costly overruns associated with weather, site issues, or material shortages.

- Lower Transportation Costs: Optimized module design can reduce the number of trips and the complexity of transportation.

- Reduced Site Disruption: Less time spent on-site means less impact on ongoing operations and potentially lower site management costs.

- Reusability and Relocatability: Many modular units can be dismantled, transported, and reassembled at a new location, offering a significant return on investment over their lifecycle.

Have you ever considered the long-term economic benefits of a building that can be repurposed or relocated? This inherent flexibility adds significant value.

The Future of Remote Infrastructure

The demand for industrial modular housing solutions for remote sites is only set to grow. As industries push further into challenging and isolated regions, the need for rapid, reliable, and sustainable infrastructure will become even more critical. Modular construction offers a proven and effective way to meet these demands.

From providing essential worker accommodation in the Arctic to establishing research outposts in deserts, or supporting emergency response teams in disaster zones, modular buildings are proving their worth. They are not just structures; they are enablers of progress, allowing industries to operate efficiently and responsibly, no matter how remote the location.

In conclusion, if your organization operates or plans to operate in remote locations, exploring industrial modular housing solutions is not just a smart choice – it's a strategic imperative. It offers a pathway to faster deployment, lower costs, enhanced sustainability, and unparalleled adaptability for your critical infrastructure needs.

For more detailed information, please visit our official website:industrial modular housing

About the author: Alex Thompson is a seasoned industry consultant with over 15 years of experience in project management and infrastructure development for remote and challenging environments. His expertise lies in optimizing logistics and resource allocation, with a particular focus on innovative construction methods like modular building. Alex is passionate about sustainable development and finding practical solutions for industrial needs worldwide.