foldable container office-with big discount

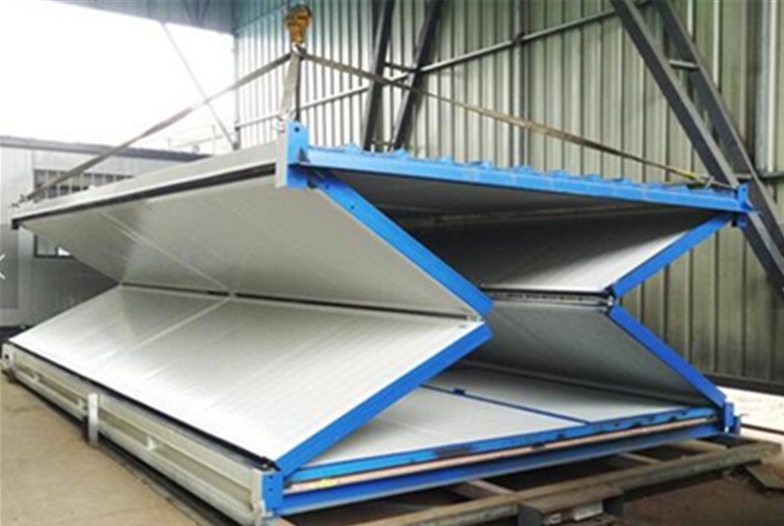

Folding Container house is a new generation of prefab house, a whole unit itself , which can be used as a single portable house, or combined laterally or placed with layers.

Openable size:5800x2480x2500mm

Folded size:5800x2480x490mm

1. Details

Main Frame:Galvanized steel+powder coating

Wall panel:

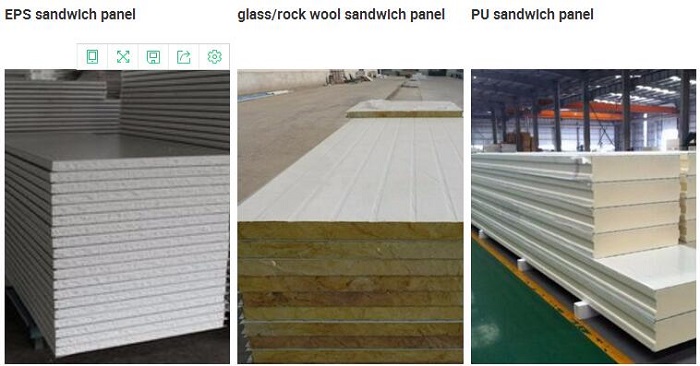

Color steel sandwich panels

Material options:EPS/Glass wool/ Rock wool/ (thickness of panel can be 50/75/100mm or custom)

Roof panel :Steel sheet with 75mm glass wool insulation

Floor:Cement fiber board/MGO board+PVC floor(optional)

Window :Sliding window

Door :Steel security door

2.Container Engineering Report

2.1 General Technical Condition

The structure can prevent the 8 magnitude earthquake.

The design of seismic grouping is the first group, the site characteristic cycle is considered 0.45s, the construction site category is considered by Class III, and the damping ratio of steel structure is 0.05. The maximum αmax of the horizontal earthquake influence coefficient is 0.04, which is calculated by 5 years.

Structural safety level is grade 2. The coefficient of importance is 1.0.

Conner fitting elevation plus or minus zero.

2.2 Materials

Normally,steel beams, steel columns, purlin are all used Q235B cold bending galvanized light steel.

strength of steel:f=215N/m²

2.3 Loading Combination

2.3.1.Calculation of floor Loading

(1)Bottom Flooring

Structure Weight 0.4 kN/m²

Dead Load Value 0.4 kN/m²

Live Load Value 3.0 kN/m²

(2)Roof board

Structure Weight 0.3 kN/m²

Dead Load Value 0.3 kN/m²

Live Load Value 0.5 kN/m²

2.3.2.Calculation of Wind loading

According to the 15 Design durable years, the basic wind pressure of wind loading is W0=0.3KN/m²

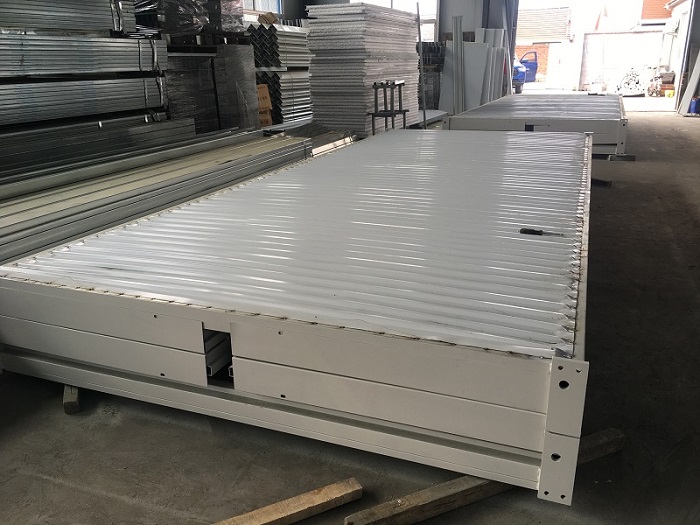

3.Container frame

top :170*2.0mm thickness frame+two layers paint

bottom:270*2.5mm thickness frame+two layers paint

column:155*2mm thickness frame+two layers paint

4.Wall&roof of foldable container house

50mm rock wool sandwich panel is standard material for wall

optional thickness 75mm,100mm.optional insulation glass wool,EPS,polyuranthane

5.Floor of folding container house

MGO board works as the bottom floor tile

and PVC tile,carpet or wood floor and be added on top of MGO board

6.Roof and ceiling of folding container house

steel plate+50mm glass wool insulation+steel ceiling

7.Window and door of folding container house

8.Delivery:

Delivery:

Delivery place: The factory is located in Weifang City, Shandong Province, China, and the nearest delivery port is Qingdao Port, China.

Delivery method: 1*40HC container can load 8 units,folded up to be loaded in container,which saves on shipping costs.

Delivery time:

Production:45 days

Delivery time:20-35 days

Therefore, we can deliver to any country in the world.

*Time may vary depending on holidays in China and the destination country and the complexity of the route to the delivery site.

9. Payment

Payment methods

T/T payment

Payment procedure

50% deposit before producing

50% balance befor delivery

10. Advantage:

install one house in 10 minutes

with insulation

galvanized frame+two layers painting,hard to get rusted

can be stacked two levels,and add veranda,canopy,railing,stair

The structure can prevent the 8 magnitude earthquake.